Thermography of Rotary Equipments

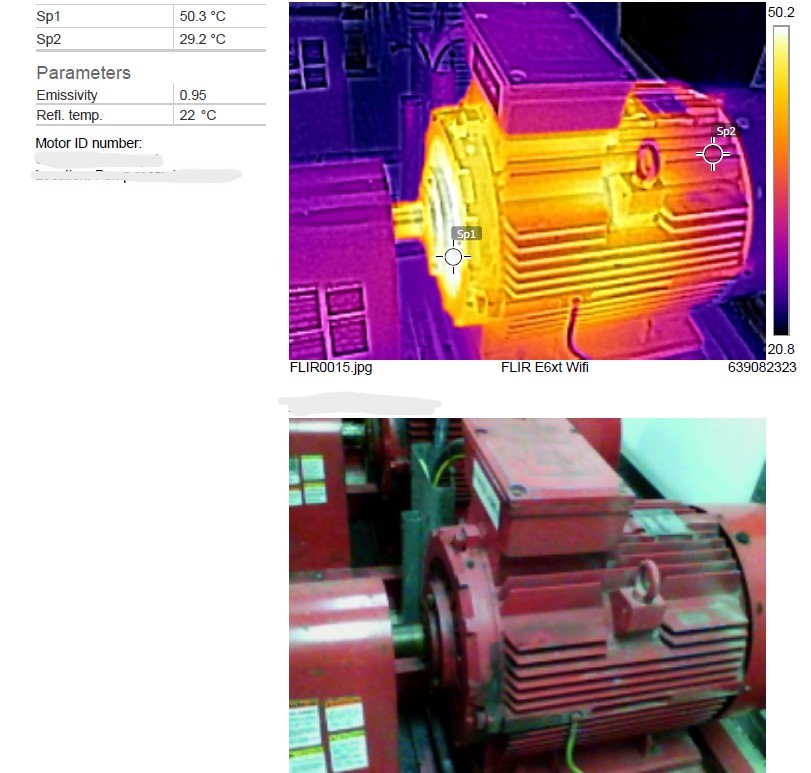

Thermography of rotary equipments, such as motors and pumps, is a critical technique for maintaining operational efficiency and safety. By using thermal imaging cameras, technicians can monitor the heat patterns of rotary equipment in real-time. This proactive approach allows early detection of issues like misalignment, bearing wear, electrical imbalance, and lubrication problems. Regular thermographic inspections of motors and pumps prevent unexpected breakdowns and ensure optimal performance across various industrial applications.

Benefits of Thermography of Rotary Equipments

Velosy Safety Consultancy is one of the leading companies doing Thermography of Rotary Equipments in UAE, offering affordable third party inspection services with competitive costs. We provide certified inspections, helping businesses obtain certificates at a reasonable price.

Early Detection of Overheating Components:

Thermography identifies overheating in motors, pumps, and other rotary equipment before failure occurs. Detecting these issues early prevents expensive repairs and unscheduled downtime.

Improved Safety:

Regular thermal inspections reduce risks associated with equipment failure, protecting employees and infrastructure from potential hazards caused by overheating or equipment malfunction.

Reduced Maintenance Costs:

Thermographic analysis allows for predictive maintenance, so issues are resolved before they turn into costly repairs. This proactive maintenance strategy minimizes wear and tear, saving money over time.

Legal Compliance:

Regular Thermography of Rotary Equipments help your business comply with workplace safety standards and avoid potential fines or legal issues.

Compliance with Industry Standards:

Thermography supports compliance with safety and operational standards by maintaining equipment integrity. This compliance prevents legal repercussions and promotes a safe work environment.

Extended Equipment Lifespan

By addressing problems early, thermography helps prolong the life of rotary equipment, ensuring that motors and pumps run smoothly and efficiently for extended periods.

Why Choose Velosy Safety Consultancy

Velosy Safety Consultancy provides expert thermographic services for rotary equipment like motors and pumps, tailored to meet your industry’s specific needs. Our team of certified specialists uses the latest thermal imaging technology to deliver accurate, reliable insights. With a focus on precision and efficiency, we ensure a thorough analysis that identifies potential issues and offers actionable solutions.

At Velosy, we pride ourselves on producing detailed, easy-to-understand reports with clear images and recommendations to guide your maintenance strategy. Our services support your commitment to safety, operational excellence, and regulatory compliance.

Choosing Velosy Safety Consultancy means partnering with a trusted provider dedicated to optimizing your equipment’s performance and safety. Our extensive industry experience allows us to address unique operational challenges effectively, ensuring that your rotary equipment remains reliable, safe, and efficient. Let us help you protect your assets and workforce with our top-tier thermographic inspection services for motors, pumps, and other rotary equipment.